Valve control DA26 F

- Product category: Electronic products

An alternative to DA modules

DA26 F converts CAN messages with lever data and safety function data into pulse width modulated current, PWM.

Depending on lever angle the DA26F supplies the positioner solenoid on the control valve with proportional current from 0 to 500 mA which in turn controls the valves spool position.

Proportionality at every stage provides superior command and control characteristic.

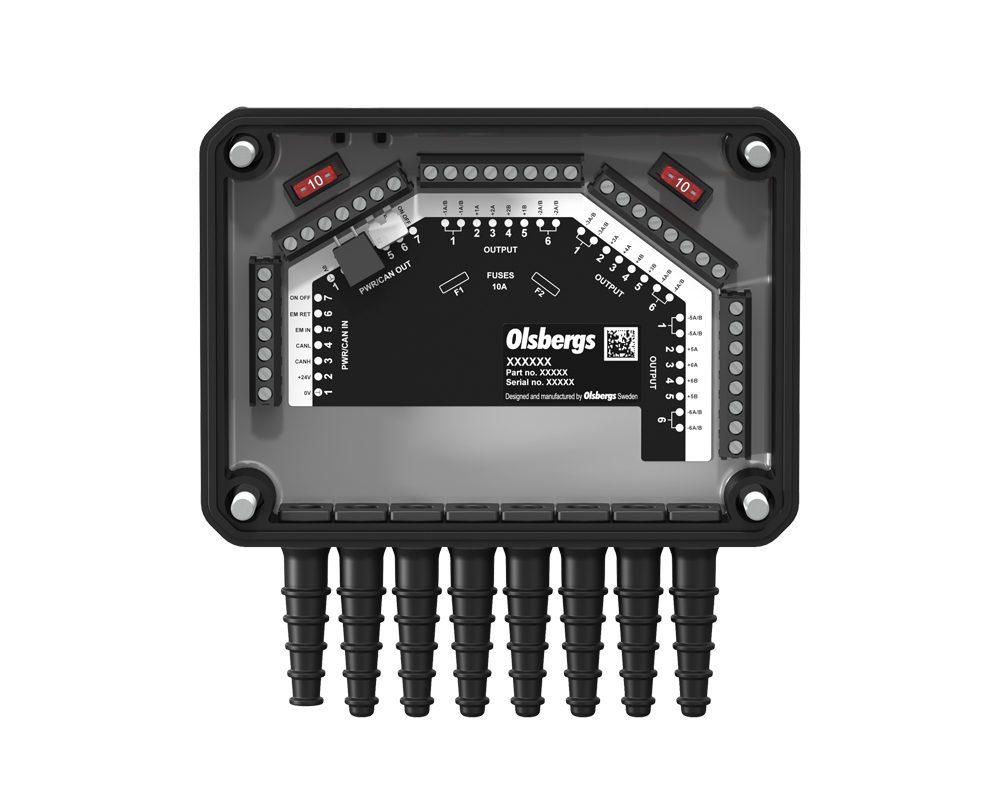

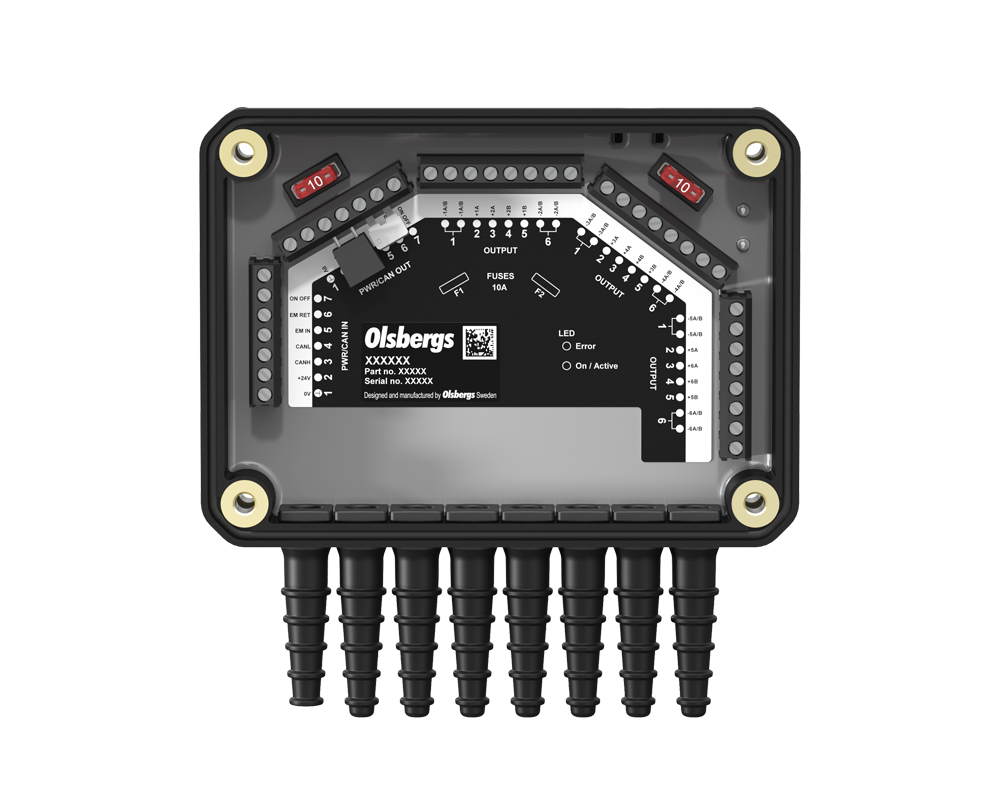

Valve control DA26F

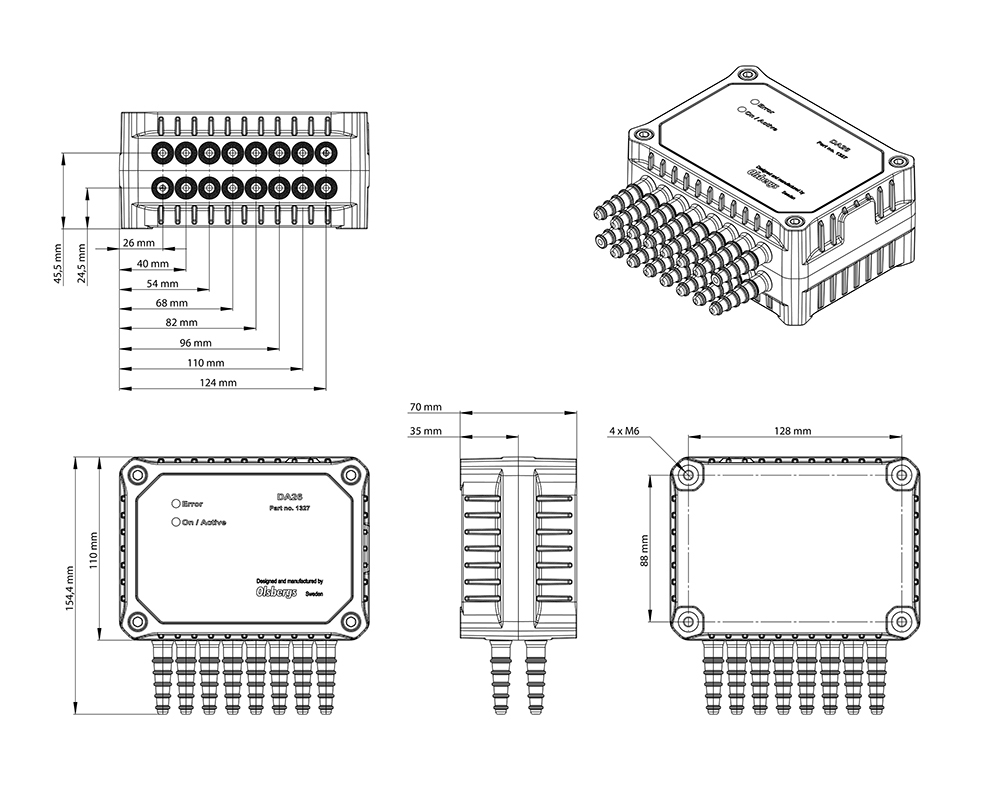

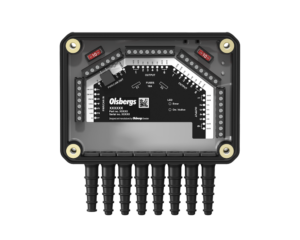

DA26 F has a modular design, top and bottom. Each top and bottom can control up to six hydraulic functions in two directions. The unit is configured based upon the number of outputs needed.

Status is indicated via two LEDs per modul.

Cablings to the positioners on the hydraulic valve

DA26F is mounted on a suitable location and from there cables go out to the control valve/valves.

DA26F is often mounted in a tough environment and is designed according to IP67 for good protection against damp, dust and dirt.

Power supply: 16 – 32 V

Max. current consumption per output: 1,5 A

Fused: 10 A

CAN Bus speed: 50 kbit/s