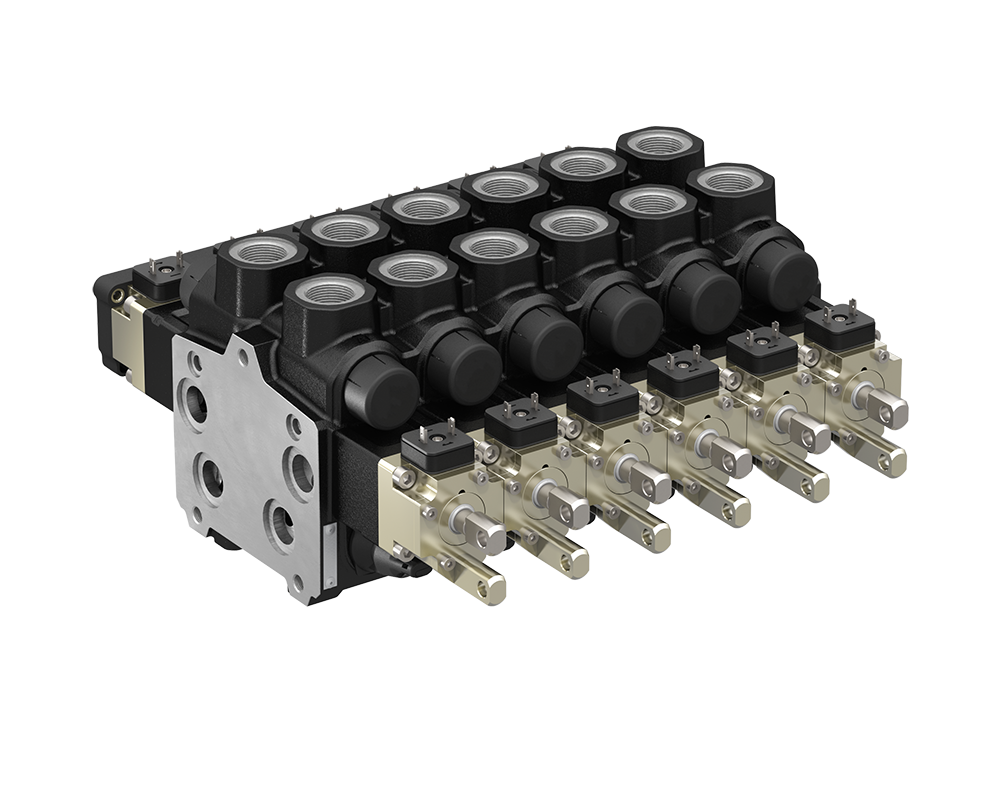

Load sensing valve Q300

- Product category: Hydraulic products

Excellent control and interaction properties

Valve Q300 is a load sensing, pressure compensated, proportional hydraulic control valve in monoblock design for a wide range of primarily mobile machinery applications. The valves can be controlled manually or electrically in combination with positioner P8.

High responsiveness and accuracy

The valve has high responsiveness and combined with Olsbergs patented mechanical valve spool return means that the valve functions can be controlled with precise proportionality without affecting flow forces.

The load-sensing Valve Q300 is the follow-up valve to the classic Olsbergs PV90M valve.

- Load sensing valve Q300 (1.39 MB)

- Olsbergs control system, hydraulics (24.08 MB)

- Olsbergs Q-serie (9.64 MB)

- Valve Q300 6-section, positioner P8 (34.93 MB)

- Valve Q300 6-section, spool ends on A-side (31.40 MB)

- Valve Q300 6-section, spool ends on B-side (31.47 MB)

- Valve protection cover, crane valve Q300 V1 (11.29 MB)

Load sensing valve Q300

Valve Q300 is a load sensing, pressure compensated, proportional valve with a wide range of applications.

Olsbergs patented mechanical valve spool return means that they can be controlled with precise proportionality without affecting flow forces.

Regeneration – for lower fuel consumption

For functions with high flow demand the there is possible to ha renegeration of the oil in order to improve operation and lower fuel consumption.

Modular system

Valve Q300 is built in three levels.

The lower level houses the pressure compensator and shuttle system. The intermediate level houses the valve spools and the upper level houses shock relief valves and anti cavitation valves.

There are a number of specially adapted inlet and outlet sections for connection to different types of hydraulic systems and pumps.

Patented mechanical valve spool return

Olsbergs patented mechanical valve spool return means that they can be controlled with precise proportionality without affecting flow forces.

In remotely controlled version of valve the valve spools are controlled by electro-hydraulic actuators, namned positioners. Via magnetic force and a servo with mechanical position return, the position of the valve spool is in direct proportion to the applied control current on the solenoid.

This results in a direct link between the control current and the flow independent of load and fluid forces.

Valve function: Load sensing, pressure compensated proportional valve

Valve type: “Closed center”

Design: Monoblock, modular, 2-, 3-, 4- or 6- “sections”

Flow (from pump): Max. 300 l/min

Flow (cylinder pump): Max. 150 l/min

Max. working pressure: 45,0 MPa (450 bar)

Servo pressure (electrically operated version): 2,0-2,5 MPa (20-25 bar)

Control: Manually or electrically with positioner P8

Connections:

Pump (P): G 3/4″

Tank (T): G 1″

Signal (S): G 3/8″

Servo (R): G 3/8″

Cylinder port A,B: G 3/4″